Innovations that are revolutionary open doors for advancement in a variety of businesses within the constantly changing field of materials science. Modified polyimide and polyamide imide are two notable polymers having a wide range of applications among the many developments. Leading this change is Harman Bawa Pvt. Ltd., an innovative business committed to expanding the realm of materials engineering possibilities.

Introduction to Harman Bawa Pvt. Ltd.:

In the materials production industry, Harman Bawa Pvt. Ltd. has made a name for itself by providing innovative solutions that cater to the changing demands of different industries. The company has demonstrated a strong dedication to research and development, resulting in the delivery of new products that have changed industry standards.

Understanding Modified Polyimide and Polyamide Imide:

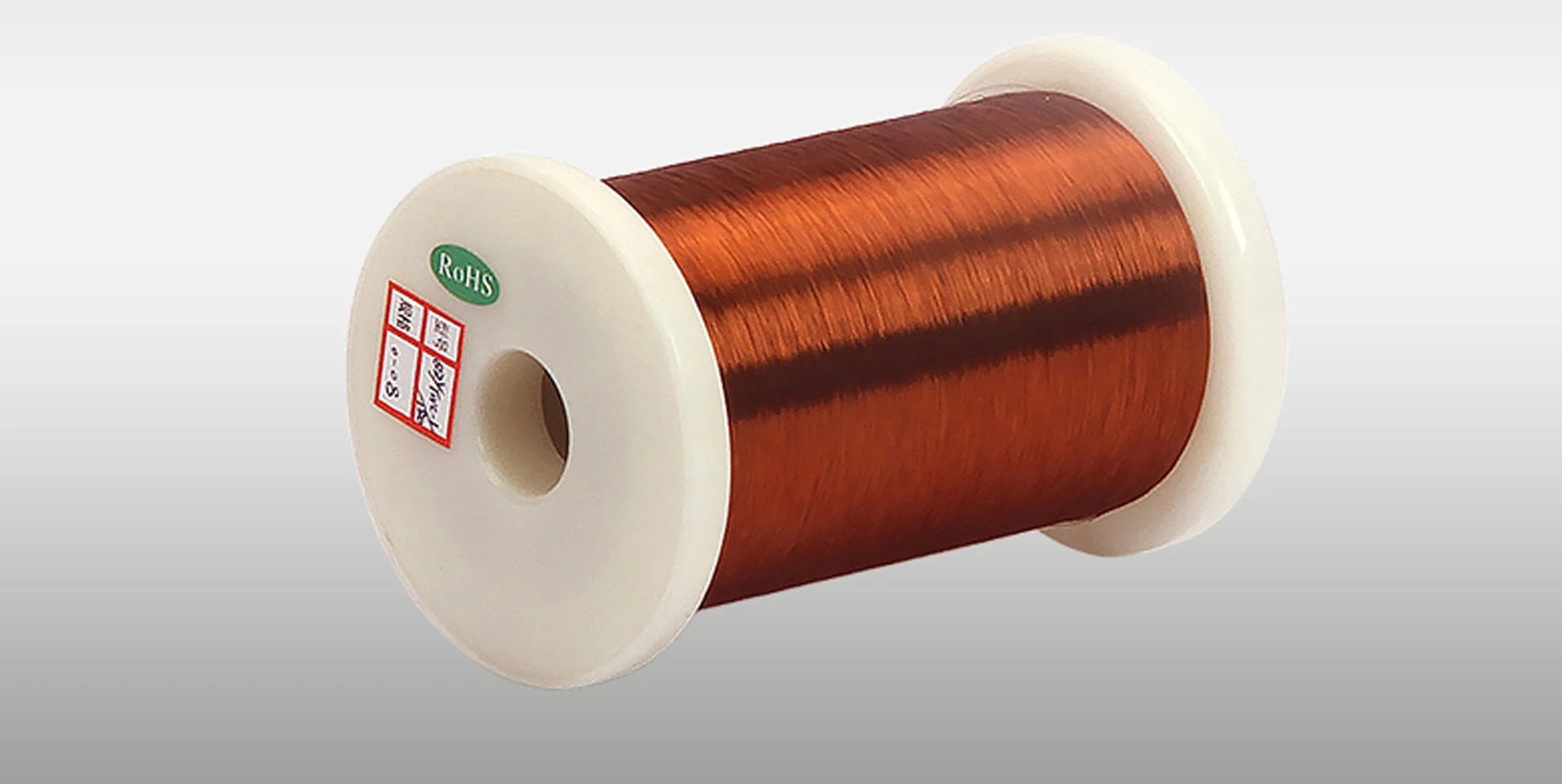

The remarkable mechanical strength, chemical resistance, and thermal stability of polyimides and polyamide imides are well known. They are extremely valuable in many different applications, including electronics, automotive, aerospace, and more because of their qualities. Nonetheless, scientists have been looking into changing these materials to improve their functionality even more.

Specific application needs are addressed by the customized characteristics of modified polyimide and polyamide imide. Harman Bawa Pvt. Ltd. has opened up new possibilities by strategically altering chemicals, allowing these materials to perform well in even the most demanding settings.

Applications Across Industries:

- Aircraft: Modified polyimide and polyamide imide are essential in the aircraft sector, where high temperatures and challenging circumstances are typical. These materials are used to create strong, lightweight parts for spacecraft and airplanes that guarantee both safety and best performance.

- Automobile: The enhanced qualities of modified polyimide and polyamide imide are very advantageous to the automobile industry. Vehicle longevity, dependability, and efficiency are all enhanced by these materials, which range from electrical insulation to engine components.

- Electronics: Miniaturization and heat management are two major issues facing the quickly developing electronics sector. Excellent dielectric qualities and thermal stability make modified polyimide and polyamide imide perfect for uses in high-temperature connectors, flexible circuit boards, and semiconductor packaging.

- Industrial Applications: These cutting-edge materials are widely used in a wide range of industrial applications, extending beyond the fields of electronics, automobiles, and aircraft. Their exceptional performance and durability, derived from protective coatings and composite materials, stimulate efficiency and innovation in several industries.

Harman Bawa Pvt. Ltd.’s Innovative Approach:

One distinguishing feature of Harman Bawa Pvt. Ltd. is its creative approach to materials development. With the help of cutting edge equipment and an experienced research staff, the company is always investigating new formulations and processing methods to improve the characteristics of modified polyimide and polyamide imide.

By utilizing a combination of extensive theoretical understanding and hands-on experimentation, Harman Bawa Pvt. Ltd. has successfully customized these materials to fulfill particular customer demands. The company’s solutions are tailored to provide best results in a variety of applications, whether the goal is to improve chemical resistance, mechanical strength, or thermal conductivity.

Collaboration and Partnerships:

To promote innovation and hasten the adoption of new technologies, Harman Bawa Pvt. Ltd. actively interacts with industry partners, academic institutions, and research organizations in addition to its internal R&D initiatives. The company’s goal is to handle complex challenges and promote positive change across sectors by utilizing pooled skills and resources.

Harman Bawa Pvt. Ltd. might explore new areas of materials research and application by gaining access to complementary technologies and viewpoints through strategic alliances. These cooperative endeavors not only augment the enterprise’s competencies but also propel the materials science ecosystem as a whole forward.

Environmental Sustainability:

Responsible manufacturing practices are important to Harman Bawa Pvt. Ltd. because we live in a time where environmental sustainability is crucial. The company delivers high-performance solutions while minimizing its environmental impact by emphasizing the use of eco-friendly materials and methods.

Furthermore, in order to make sure that its products adhere to the principles of the circular economy, Harman Bawa Pvt. Ltd. actively investigates solutions for their products’ biodegradability and recyclability. The organization aims to make a positive impact on future generations by promoting sustainability through ongoing innovation and improvement.

Conclusion:

Innovation is the foundation of development, and modified polyimide and polyamide imide are two examples of how Harman Bawa Pvt. Ltd. has pioneered this philosophy. The company is enabling businesses to prosper in a world that is constantly changing and transforming industries by pushing the boundaries of materials science and engineering.

The promise of these cutting-edge materials is endless as we look to the future, and Harman Bawa Pvt. Ltd. is still at the forefront of realizing their full potential. One breakthrough at a time, the company is making the impossible possible by shaping the future of materials technology with an unwavering dedication to excellence and a passion for innovation.